- Steel Structure

- Steel Structure Warehouse

- Steel Structure Workshop

- Steel Structure Building

- Prefabricated House

- Container House

- Poultry House

- Sandwich Panel

- Steel Structure Chicken House

- Steel Structure Material

- Poultry House

- Sandwich Panel

- Shipping Container House

- Modular Container House

- Prefabricated Home

- Steel Structure Poultry House

Modern Design Large Span Easy Assemble Prefabricated Steel Structure Heavy Industrial Workshop

Basic Info

| Model NO. | RULYY0039 |

| After-sales Service | Installation Guidance on Construction Site |

| Warranty | According to Project Type |

| Type | H-Section Steel |

| Standard | GB, ASTM, DIN, JIS, AISI, BS |

| Trademark | Low-alloy High-tensile Structural Steel, Ruly Steel |

| Connection Form | Bolt Connection |

| Type of Steel For Building Structure | High-Strength Steel |

| Carbon Structural Steel | Q235 |

| Application | Steel Workshop, Steel Structure Platform, Structural Roofing, Frame Part |

| Usage | Steel Structure Car Park |

| Size | Customized |

| Features | Prefab Steel Structure,Large Span,Multi-Floor |

| Raw Steel Material | Q235B, Q355b,ASTM A36 |

| Surface Treatment | Painting or Hot-DIP Galvanized |

| Service Life | 50 Years |

| Wall and Roof | Steel Cladding Sheet,Sandwich Panel |

| Parapet Wall | as Requested |

| Columns & Beams | H-Section Steel |

| Installation | Engineer Guidance on Site |

| Shot Blasting Level | SA 2.5 |

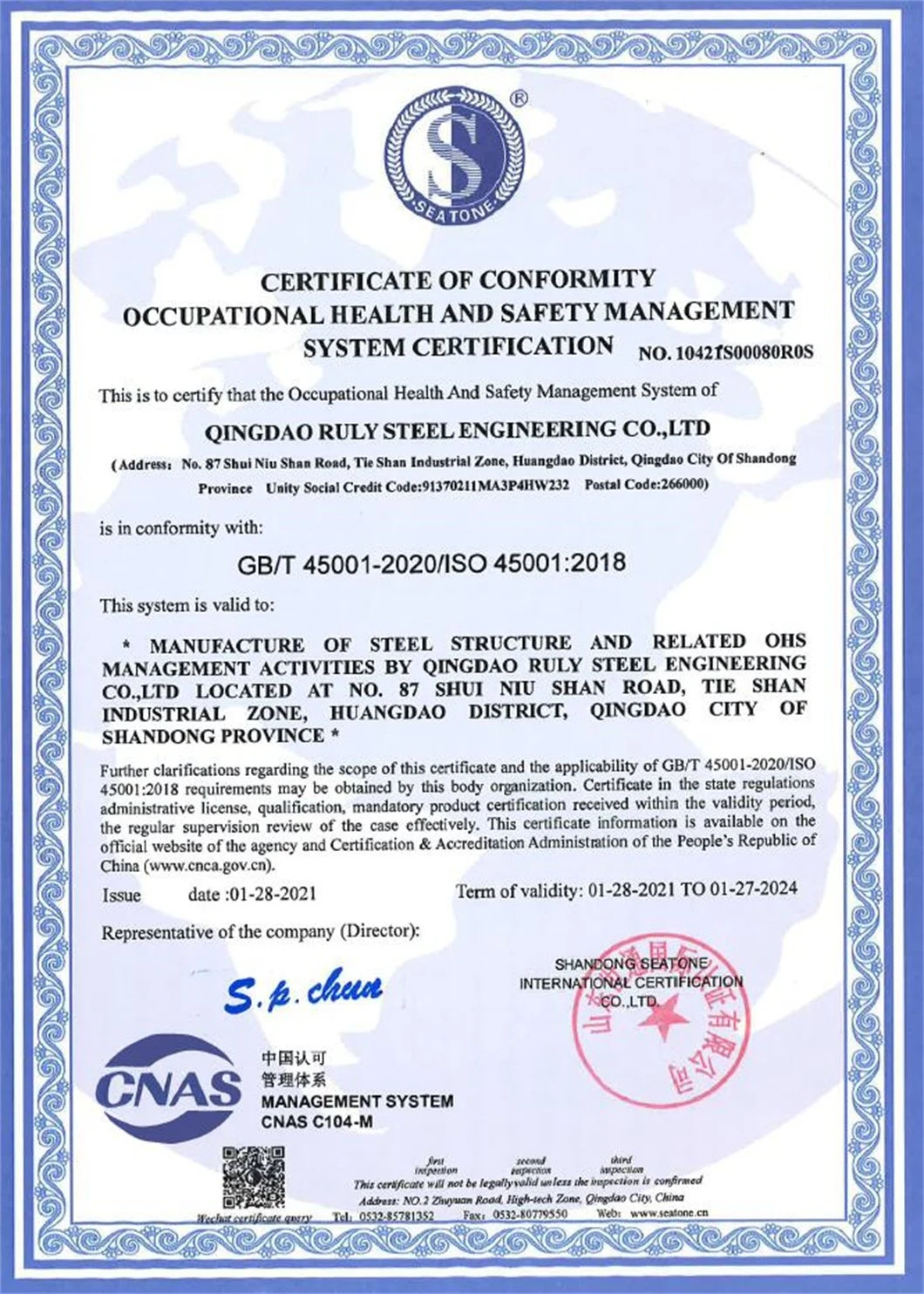

| Certification | CE,Aisc,SGS, BV, ISO,GB |

| Color | Customizable |

| Drawing | CAD,Tekla,,3D Model, Pkpm,Bim |

| Transport Package | Standard Export Package or Customer′s Requirement |

| Specification | Square Meter |

| Origin | Qingdao, China |

| HS Code | 9406900090 |

| Production Capacity | 30000ton/Year |

Product Description

Modern Design Large Span Easy Assemble Prefabricated Steel Structure Heavy Industrial Workshop

Product Features:Steel structure has been widely used in many buildings. This is a steel structure workshop. Compared with the traditional concrete building, the available area of the steel structure workshop is larger, more stable and reliable, and at the same time, it has the characteristics of fire and shock.

We can provide personalized customization, according to your requirements to design, at the same time, our product quality is absolutely guaranteed.

The construction materials of steel structure are easy to transport, convenient to assemble, save a lot of time, beautiful appearance, simple, economical, cost-effective.

| Material list and technical parameters for steel structure components and accessory: |

| Steel Frame | H section steel | Q235/Q345 steel plate thickness: 8-30mm |

| Welding | Automatic submerged arc welding | |

| Rust removal | Sand blasting | |

| Surface finish | Alkyd paint or galvanized | |

| Intensive bolt | M20,Grade 10.9 | |

| Supporting System | Angle brace | L50x4,Steel Q235, processed and painted |

| Horizontal brace | Φ20, Steel Q235, processed and painted | |

| Column brance | Φ20, Steel Q235, processed and painted | |

| Tie rod | Φ89*3, Steel Q235, processed and painted | |

| Ordinary bolt | M12 Galvanized bolt | |

| Roof | Purlin | C160*60*2.5,Steel Q235, galvanized and painted |

| Roof panel | Sandwich panel or corrugated steel sheet | |

| Sky light | 6mm thick PVC | |

| Accessories | Glass cement, self-tapping screws, etc. | |

| Edge cover | 0.4mm steel sheet profile trimming | |

| Gutter | 0.4mm thick sheet steel profile or galvanized sheet | |

| Down pie | Φ110PVC | |

| Walls | Purlin | C160*60*2.5,Steel Q235, painted |

| Wall | Sandwich panel or corrugated steel plate | |

| Accessories | Glass cement, self-tapping screws, etc. | |

| Edge cover | 0.4mm steel sheet profile trimming | |

| Ventilation | Ventilation ball | |

| Doors & windows | Rolling door/sliding door PVC/alu/steel/window |

| About our company,certifications and highlight projects: |

Qingdao Ruly Steel Engineering is a professional steel structure fabrication and engineering company, located in Qingdao, China, which integrates steel structure design, research and development, manufacturing and installation. The project types include prefabricated steel workshop, warehouse, logistics park and other light steel structure of the civil building system, high-rise residential buildings, exhibition center, stadium, airport station and bridge, Power plant, chemical plant, oil and gas, mining,etc. Our company's steel structure processing plant now covers an area of 35,000 square meters, plant20,000 square meters. More than 100 employees. The monthly production capacity for steel structure is more than 1500 Tons. Our steel structure componetns include light/heavy H steel ,BOX steel,Cross shaped section steel, large diameter submerged arc straight-weld pipe,steel model structure, C/Z purlin and machining fitting components . There are three subordinate steel structure companies, which have passed and strictly implemented ISO9001:2008 quality management system, ISO14001:2004 environmental system, GB/T28001:2001 occupational health system, and obtained ASTM certification in the United States, and international SGS product certification. Obtained the right of export, design, installation and consultation from the ministry of foreign trade and economic cooperation.Quality first, Technology ahead ,Innovation continually is our entrepreneurial concept. We build strong relationships of trust with our clients, truly understanding their needs and bringing them the most reasonable solutions.

| Our steel structure fabricaiton factory: |

| Installation: |

Method 1: We provide shop drawing before installation.

Method 2: If you still don't know how to install, We will teach you the installation in our factory. when necessary , we will assemble a sample steel structure building for you.

| Quality Control: |

| Packing & Loading: |

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

| Why us? |

1. Professional design team, we could design the drawing as your requirement or calculate the steel quantity based on your drawing.

2. Skilled fabrication team and advanced equipment. We make the independent production schedule to each project.

3. One-stop service: We have completed lots such kinds of projects, we could provide the integrated proposal for your project.

4. Professional QC team will guarantee that we will provide the production and service as your request.

5. After sales service: If it has any questions that need us to do in your process of using, such as the maintain of outside insulation and steel components, just tell us , we will try to provide the service as well as we can.

| How to quote: |

The following question we need to know before making the price. Just feel free to fill what you know.

| 1 | Location (where will it be built?) | _____country, area |

| 2 | Size: length*width*height | _____mm*_____mm*_____mm |

| 3 | wind load (max. wind speed) | _____kn/m2, _____km/h, _____m/s |

| 4 | snow load (max. snow height) | _____kn/m2, _____mm |

| 5 | anti-earthquake | _____level |

| 6 | brickwall needed or not | If yes, 1.2m high or 1.5m high |

| 7 | thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; . if not, the metal steel sheets will be ok. The cost of the latter will be muchlower than that of the former |

| 8 | door quantity & size | _____units, _____(width)mm*_____(height)mm |

| 9 | window quanity & size | _____units, _____(width)mm*_____(height)mm |

| 10 | crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |