- Steel Structure

- Steel Structure Warehouse

- Steel Structure Workshop

- Steel Structure Building

- Prefabricated House

- Container House

- Poultry House

- Sandwich Panel

- Steel Structure Chicken House

- Steel Structure Material

- Poultry House

- Sandwich Panel

- Shipping Container House

- Modular Container House

- Prefabricated Home

- Steel Structure Poultry House

Prefabricate Building with High Stability Steel Structure Workshop

Basic Info

| Model NO. | XGZ |

| Warranty | 1 Year |

| Material | Steel Structure |

| Usage | Warehouse, Villa, Workshop, Building Factory |

| Customized | Customized |

| Certificationteel St | ISO, CE, SGS |

| Design Code | Wind Load, Snow Load and Earthquake |

| Service Life | More Than 50 Years |

| Installation | Engineer Helps Instruct Installation |

| Drawing Design | Autocad, 3D3s, etc.. |

| Technology | Welded Steel, Hot Rolled Steel |

| Purlin | C/Z/H Profile |

| Transport Package | Steel Pallet |

| Specification | Q235, Q345 |

| Trademark | XGZ |

| Origin | China Qingdao |

| HS Code | 9406900090 |

| Production Capacity | 3000 Tons/Month |

Packaging & Delivery

Package size per unit product 12.00cm * 2.35cm * 2.69cm Gross weight per unit product 22000.000kgProduct Description

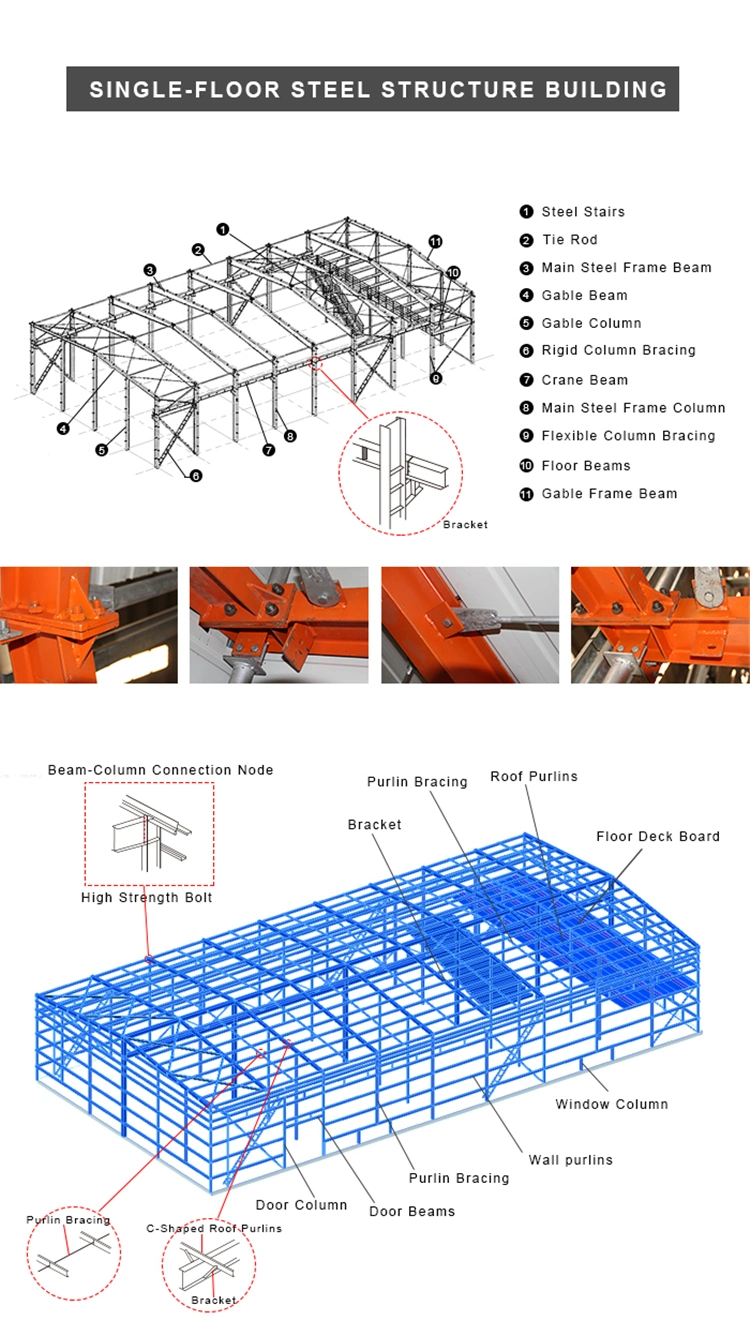

Prefabricate Building with High Stability Steel Structure Workshop

Product Description of Steel Structure Workshop:

1. Our Steel Roof Structure with the color steel sandwich panel, can bear wind load 100km/h and 7 grade earthquake, with fire proof and heat insulation. 2. Superiority: Saving more space of the container and make the cost of house lower, easy to assemble and disassemble, using life over 20 years. The waterproof system on the roof makes the Steel Structure Warehouse a good sealing effect. 3. Application: Can be used for temporary office, accommodation, entertainment and school room quickly and large quantity. 4. Others: Steel Structure Warehouse, Steel Structure storehouse, Steel Structure Workshop, A36 steel structure, steel structure building, steel construction, steel skeleton construction, steel work, Structure metal framing etc.

Detailed Photos1. Column, Beam: H section steels with anti-rust grey painting

2. Purlin: Galvanization Purlins

3. Secondary Support: Galvanization, e.g. Tie Bracing, Bracing Bars, Angle Steels, all these will improve the stability and durability of the whole structural building.

4. Roof & Wall: Alu-zinc color-coated steel sheet in the thickness of 0.5mm

5. Window: Aluminum-alloy sliding windows

6. Door: Steel Door, Fire-proof Door

Packaging & Shipping

Qingdao Xinguangzheng Husbandry is a subsidiary of Qingdao Xinguangzheng Group.It has independent professional product development and design,manufacturing,engineering and installation capabilities,and providing intelligent integrated husbandary services to customers around the world.The company has always been committed to the use of state-of-the-art science and technology and develop product solutions for the global livestock industry,providig complete technical support,from home-based farms to complete solutions for complex commercial farms,and is always closed to national markets through communication and cooperation. The company has formed a research and development team for the chicken house project with elite technicians,Through the project research and study,the decomposition of the house building,the internal and external training of the science profession,the company has formed a unique series of standardized chicken houses.We can provide the service of installation, supervision and training by extra. We can send our professional technical engineers to supervise installation on site overseas. Besides, we also have our own abroad guiding installation team consisting of more than 30 people.

FAQ1. Why choose us? We are a steel structural building Manufacturer located in Qingdao, China, We have gained a good reputation among our customers for our professional, warm and thoughtful service. Because we know that a long terms business is based on the quality control, price, packing, delivery time etc. 2. Does your company is a factory or trade company? We are a factory, so you will get the best and competitive price. Our factory covers an area of 150, 000 square meters. If it is available, you might as well visit us. 3. What's the quality assurance you provided and how do you control quality? Established a procedure to check products at all stages of the manufacturing process - from raw materials, processing, testing or inspection, to finished goods, etc. 4. What's the delivery time? After we got you deposit, we can deliver goods within 30 days. 5. Can you offer designing service? Yes, we have more than 100 design engineers. We could design full solution drawings as per your requirements. The software we used here are Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)V12.0. etc. 6. Do you offer guiding installation on site overseas? Yes, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineers to supervise installation on site overseas. Besides, we also have our own abroad guiding installation team consisting of more than 30 people. They have finished many cases successfully in many countries, such as Iraq, Dubai, South Africa, Algeria, Ghana, Gabon, Tajikistan, Burkina Faso, Panama, Australia and so on.